Foundry Equipment in this Ordered Liquidation

- Featured Equipment

- Equipment Details

- Sand Systems

- Melt Shop

- Straightning Press

- Material Handler w/Magnet

- Front End Loader

- Street Sweeper

- Shot Blasting Equipment

- Car-Bottom Heat Treat Furnaces

- Overhead Bridge Cranes

- Magnetic Particle Inspection

- Molding Systems

- Metallurgical Lab

- Pattern Shop

- Electrical Switchgear

- Air Compressor Systems

- Cooling Circuit Equipment

- Herr Voss Tension Leveling Line

Featured Equipment

Equipment Details

Sand Systems

- General Kinematics 18' X 14' Shakeout Deck, new 2013, never installed, two-mass design, approx. 60 ton capacity

- Gudgeon Thermfire Thermal Reclaimer Model TF8000, new 2010, Allen Bradley PLC controls, 96 tons per day/480 tons per week thruput, 5 x 1.5 million BTU Kinemax burners, Castec Cel-300 feeder, S/N 1176

- Gudgeon Thermfire Sand Heater/Cooler/Classifier Model RES-A026, new 2010, S/N 1179

- (2) General Kinematics Vibra-Mill Lump Breakers, programmable controller, S/N C10495-02, S/N N/A

- Several Macawber & Whirl-Air Flow Sand Transporters W/ Allen Bradley Programmable Controller

- (3) Large Modular Construction Sand Bins

- Eriez Electromagnet Model MC2SE7330, 33.1-amp, 115 v., S/N 291022

- (2) Hi-Vac Electric Powered Sand Vacuum Systems, one unit rebuilt 2022, with dump hoppers & hoses

Melt Shop

- (3) Whiting 9' Diameter Hydro-Arc Melting Furnaces, approx. 8 t. capacity, hyd. Tilt drive, Pennsylvania 4,000 KVA type OW transformer, 13,200 V primary, recently retrofitted with Tenova model LPV4043 servo electrode control system, auto tap changer, auto vacuum breaker, Nidec variable frequency drives, several new copper lead sets, several spare furnace roofs, quantity of new electrodes, ductwork & fume/dust collector system

- (2) Gas Fired Ladle Pre-Heat Systems

- (2) 10 T. Cap. Ladle Handlers

- (8) 10 T. Cap. Bottom Pour Ladles

- (2) Bottom-Drop Clam Shell Scrap Buckets

- Large Qty. Slag Pots

- Walker 54" Crane Magnet

- (3) Cardox Fire Suppression Systems

Straightning Press

- Dake 300 T. Cap. Hydraulic Straightening Press

Material Handler w/Magnet

- Atlas Model 300mh, new 2013, diesel, wheeled, 2,000-lb. cap., outriggers, dual solid tires on front and rear, H.O.M.: 9,040, S/N 301266. Equipped w/Walker Model 4505H 45" dia. magnet, S/N 14D53

Front End Loader

- John Deere Articulated Model 444J High Lift, S/N DW444JH612883

Street Sweeper

- Elgin Model Pelican Series SE, 3-wheel mechanical boom sweeper w/isolation mounted cab

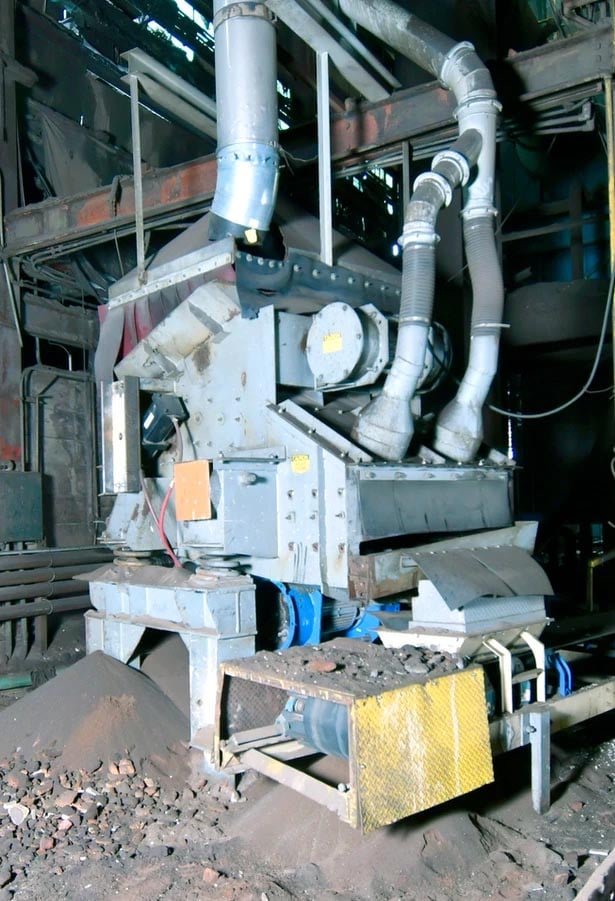

Shot Blasting Equipment

- Wheelabrator 63" X 96" "Tumblast" Shotblasting Machine, skip loader unit, 50 HP direct drive 24" dia. Wheel, Wheelabrator shaker style dust collector, S/N A56540

- Wheelabrator Table Blast Machine, 72" dia. Extra heavy cap. Tbl., manganese steel lining, recirculating shot system, 50 HP direct drive shot wheel, 500 lb. shot hopper w/ air feed system, Torit cartridge style dust collector, S/N NA

- Free Standing Blast Room, approx. 15' wide x 20' deep x 15' ht., H.D. rail car, winch system, unitized panel construction, recirculating media system, dust collection system, Axxiom 10 cu. Ft. blast pot w/shot filtration system new 2019,

Car-Bottom Heat Treat Furnaces

- Bevermatic Car-Bottom Furnace Model 12X8X12DGCBF, new 2012, 12' W x 12' L x 8' H interior dimensions, 72,000 lb. car weight cap., 1,850 deg. Max. temp. 350 deg. Min. temp., ceramic wool lining, pwr. car, Maxon Model 300SMA11-A11-B21A0 shut-off valves, Dungs combustion controls, (10) total burners, S/N 1011-175/8

- Bevermatic Car-Bottom Furnace Model 7X14X7DGCBF, 7' W x 14' L x 7' H interior dimensions, 30,000 lb. car weight cap., 1,850 deg. Max. temp. 500 deg. Min. temp., ceramic wool lining, pwr. car, (this furnace is currently needing a relining) S/N 40153/8

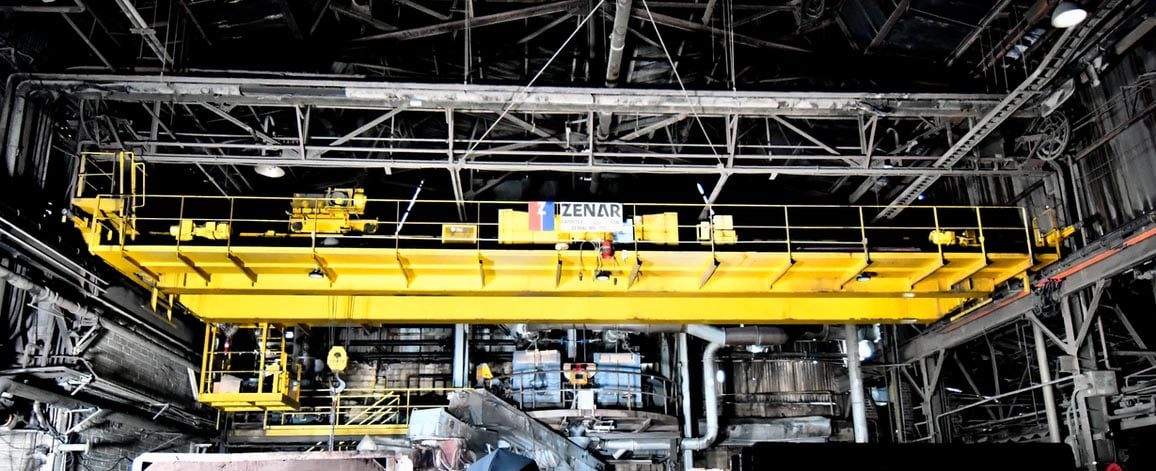

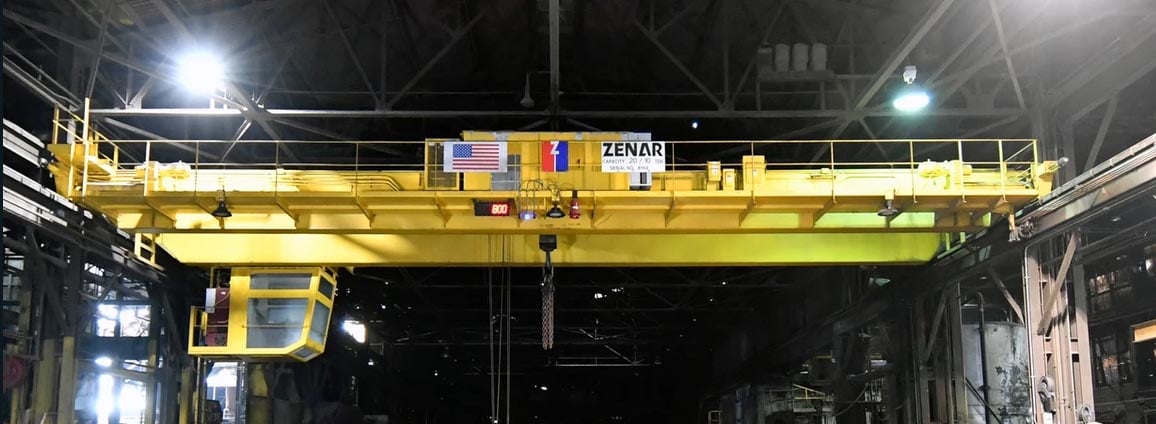

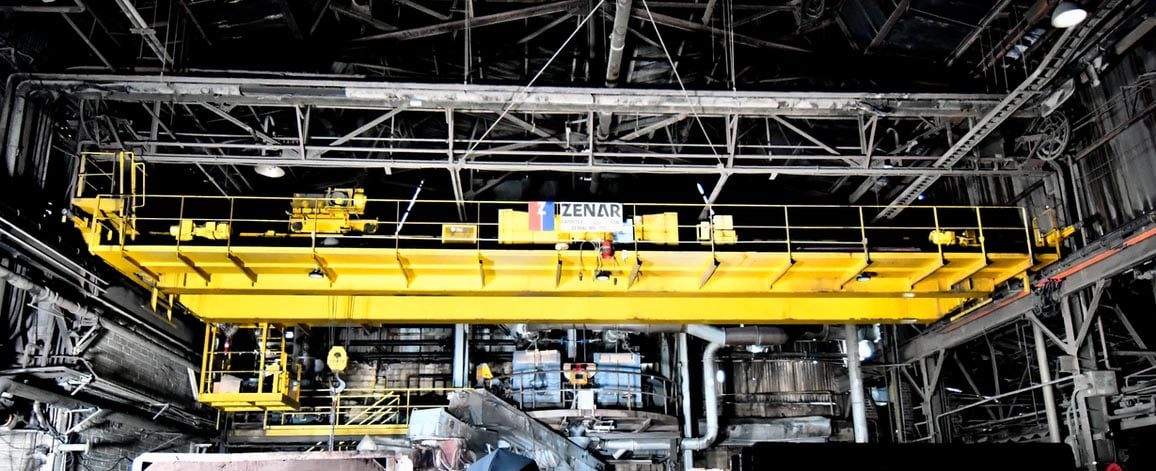

Overhead Bridge Cranes

- Zenar 20/10 Ton Top Running Double Girder Hot Metal Crane, new 2022, Class E rated, cab/radio controls, 20 T. cap. Main hoist, 10 T. cap. Aux. hoist, 63'-2-1/4" span, 30' lift ht., digital crane scale w/ read-out, full-length service platform, S/N 8914 (new cost, $732,000.00)

- Zenar 20 Ton Top Running Double Girder Hot Metal Crane, new 2014, Class E rated, cab/radio controls, 20 T. cap. Main hoist, 63'-2-1/4" span, 30' lift ht., full-length service platform S/N 8565

- Zenar 15 Ton Top Running, Double Girder Crane, 55' pprox.. span, cab/radio controlled, S/N 4880

Magnetic Particle Inspection

- Magnaflux Model CSV-20, 20,000 max. output amps fwdc, remote control stand, 5 gal. spray pot w/ agitator, spray head, (2) 24" x 48" copper plate material stands, S/N 623432-01

- Several Magnaflux Magnetic Particle Inspection Machines

Molding Systems

- Kloster Versa-Mull Type III Double Articulated Mixer, 2,000-lb. per minute cap., operator’s pulpit w/joystick controls, pwr. rotation primary and both secondary arms, 8'-6" discharge ht., 14' primary arm reach, 5' secondary arm reach, 24'-3" max. reach, 50 HP, Alfaset resin system, Kloster 60 TPM sand heater/cooler/classifier, (2) large rectangular compaction tables, S/N 8097-VM3-2000, system installed 2009.

- Tinker Omega Articulated Mixer Model TOM1200, 1200-lb. per minute cap., Next Gen 2 PLC controls, pwr. primary and secondary arm rotation, Alfaset resin system, feed hopper, pneumatic transporter, (2) Kloster 45 TPH sand heater/cooler/classifiers, vibratory compaction tbl., H. D. roller conveyor molding line, 90 deg. turn unit, Kloster boiler and dust collector, system installed 2010.

- Kloster Versa-Mull Type II Articulated Mixer, 1,000-lb. per minute cap., pwr. primary arm rotation, 7'-3" discharge ht., 11'-8" primary arm reach, 15'-8" total reach, Alfaset resin system, feed hopper, Palmer additive system, Kloster 60 TPH sand heater/cooler/classifier, S/N MS-7428-VN2-1000, installed 2011.

Metallurgical Lab

- Leco Model ONH836 Elemental Analyser, pwr. purification system, vacuum

- Leco TCH600 Elemental Analyzer

- Applied Research Spectrometer Model 3460, 9-Elements, S/N 2144

- Watgate Technologies Structurix NDT-U X-Ray Film Developer (New 2022)

- Tinius Olson Tensile Tester, Hyd. Drive, Computer Read-Out

- Tinius Olson Model 84 Charpy Impact Tester

- Amatek Steel Testing Machines Inc. Brinell Testing Machine

- Wilson Rockwell Hardness Tester Model 5JRBB, S/N 1510

- Hitachi-Seiki TSl15 Cnc Lathe, Siecos 21l CNC Control, 6" 3-Jaw Chuck

- Index Vertical Turret Mill

- Thermoline Oven

- Heavy Duty Electric Furnace, 1850° F

- Heavy Duty Furnance Model HD10187, 2,000° F, S/N 81212

- Baileigh Engine Lathe Model Pl1236DRO

- Abell Howe 1/2 T. Cap. Jib Crane

- Hydmech Mitering Horiz. Bandsaw Model S20, S/N 20195057

- Kalamazoo 6" Belt Sander

- Carborundum Abrasive Cut-Off Saw

Pattern Shop

Complete Pattern Shop Including:

- Delta Rockwell Vertical Bandsaw

- Walker Turner Radial Drill

- Ridgid Compound Miter Saw

- Stencil Machines

- Walker Turner Verical Bandsaw

- Spindle Sanders

- Delta Table Saw

- Jointer

- 14" Delta Planer

- Bever Vertical Turret Mill

- Scroll Saw

- Tilt Frame Vertical Bandsaw, Model No. 8MK1, S/N 82174

Electrical Switchgear

Huge assortment of transformers, circuit breakers, motor control centers, and related electrical gear serving up to 13,200 volt power systems. All electrical systems with this facility are for sale. a single line electrical diagram is available upon request.

Air Compressor Systems

- (3) Sullair 200 Hp Water Cooled Rotary Screw Air Compressors (two units recently rebuilt)

- Atlas Copco Model FD-1750 Refrigerated Air Dryer, new 2019, 1,750 CFM capacity

Cooling Circuit Equipment

- (2) Evapco Cooling Tower Model AT19-2H8, qty. of (4) 7 ½ HP vertical pumps, butterfly valves, S/N 21P118711

- Trane 300 T, Chiller System

Herr Voss Tension Leveling Line

Description: 37" X .063" X 27,000# Herr Voss Tension Leveling Line, YR 1992 (Located in storage facility in Mansfield Ohio)

General Line Specifications:

- Manufacturer - Herr Voss

- Year - 1992

- Material - Stainlesss Steel & Inconel

- Yield - 100,000 PSI Max

- Shear Strength - 80,000 PSI Max

- Coil Weight - 27,000#

- Max Coil Width - 37"

- Min Coil Width - 24"

- Coil Range - 60"

- Coil ID - 20"

- Gauge Range - .008" - .063"

- Line Speed - 300-600 FPM

- Electricity - 480 V, 3 PH, 60 Cycle

- Line Direction - Left To Right

- Status - Installed And Operating

Line Components:

- L-Shaped Traversing Elevating Coil Car

-

Mandrel Uncoiler W/ Overarm Snubber Roll & Paper Winder

- Hydraulic Expansion

- Wichita Water Cooled Brake

-

Hydraulic Peeler Table

- Polyerothane Entry Pinch Rolls

- Edge Guide System

-

Entry Hydraulic Crop Shear

- Scrap Cart

- Exit Table

- Vertical Pinch Roll Centering Guides

-

Behlen Stitcher

- Entry Roller Guide

-

4-Roll S-Type Drag Tension Bridle Rolls

- Each Roll Motor Connected To Nuttal Gear Box And Universal Connection To Roll

- #1 Roll Motor - 15 HP

- #2 Roll Motor - 25 HP

- #3 Roll Motor - 50 HP

- #4 Roll Motor - 100 HP

-

5-Roll Precision Tension Leveler - 3 Over 2

- Leveler Pivot Device

- 1 1/2" Diameter Leveling Rolls

-

(4) Roll S-Type Drive Tension Bridle Rolls

- Each Roll Motor Connected To Nuttal Gear Box And Universal Connection To Roll

- #1 Roll Motor - 150 HP

- #2 Roll Motor - 100 HP

- #3 Roll Motor - 50 HP

- #4 Roll Motor - 25 HP

- 6' Inspection Table

- Thickness Gauge (Source Not Included)

-

Exit Hydraulic Crop Shear

- Scrap Cart

-

Hydraulic Exit Carroyover Table

- Edge Guide System

- Deflector Roll

- Paper Unwinder

- Hydraulic Threading Table

-

Mandrell Uncoiler With Holddown Roll

- Hydraulic Expansion

- Belt Wrapper

- L-Shaped Traversing Elevating Coil Car

- Electrics - Ge Drive Systems

- Controls, Electrics, Hydraulic Unit

Watch this machine in action!

To make an appointment to view equipment, ask questions, or buy machinery contact equipment expert Steve Nelson today!

All items subject to prior sale.

steve@fedequip.com

steve@fedequip.com 281.686.6979

281.686.6979